Storage, Handling and Transport Validation of Medical Devices

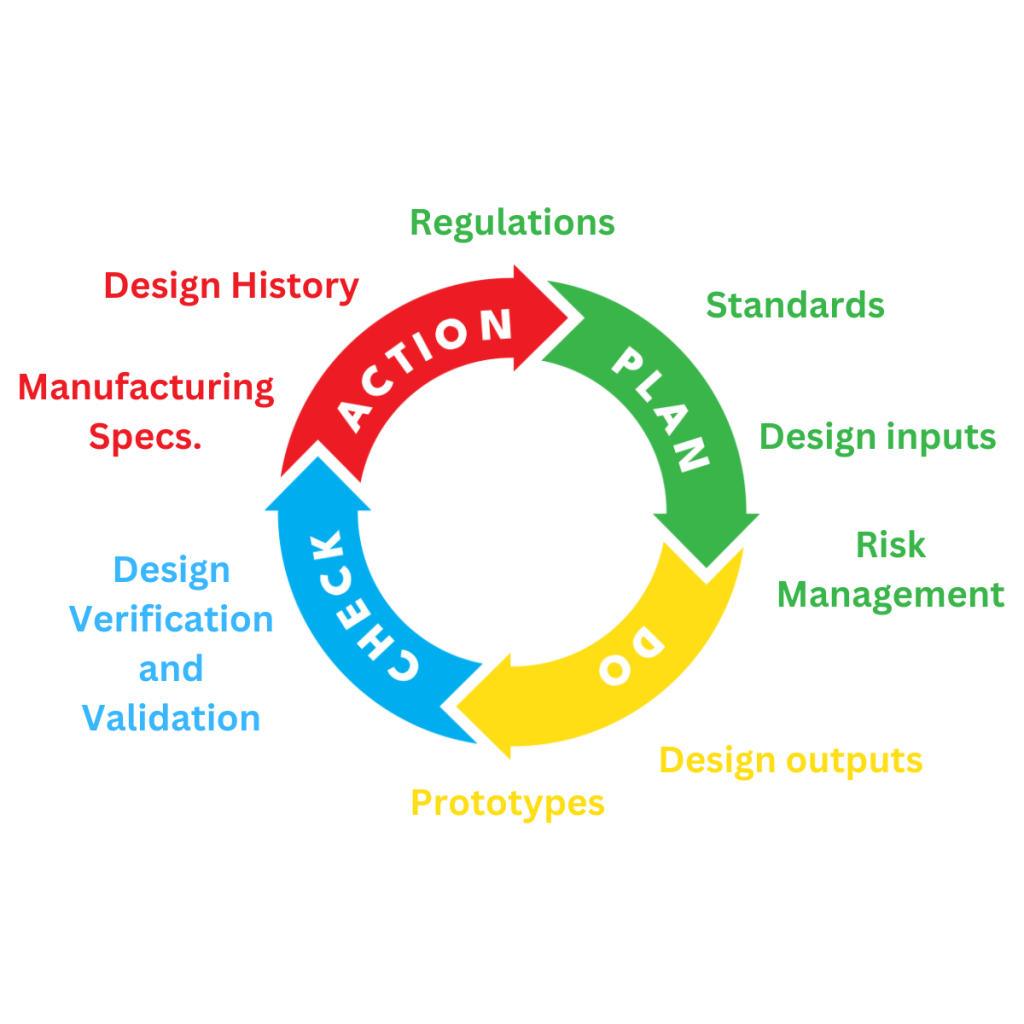

Ensuring the safety, integrity, and effectiveness of medical devices requires strict control over their storage, handling, and transport. Medical devices are sensitive to environmental conditions such as temperature, humidity, and mechanical stress, which can compromise their functionality and sterility. Compliance with international regulatory standards, including ISO 13485, ISO 14971, EU MDR, and FDA guidelines, is essential to mitigate risks associated with storage and distribution. Through proper validation of these processes, manufacturers and suppliers can prevent product degradation, avoid regulatory penalties, and ensure patient safety. This blog explores the importance of storage, handling, and transport validation, key regulatory requirements, and best practices for ensuring compliance.

Storage, Handling and Transport Validation of Medical Devices Read More »